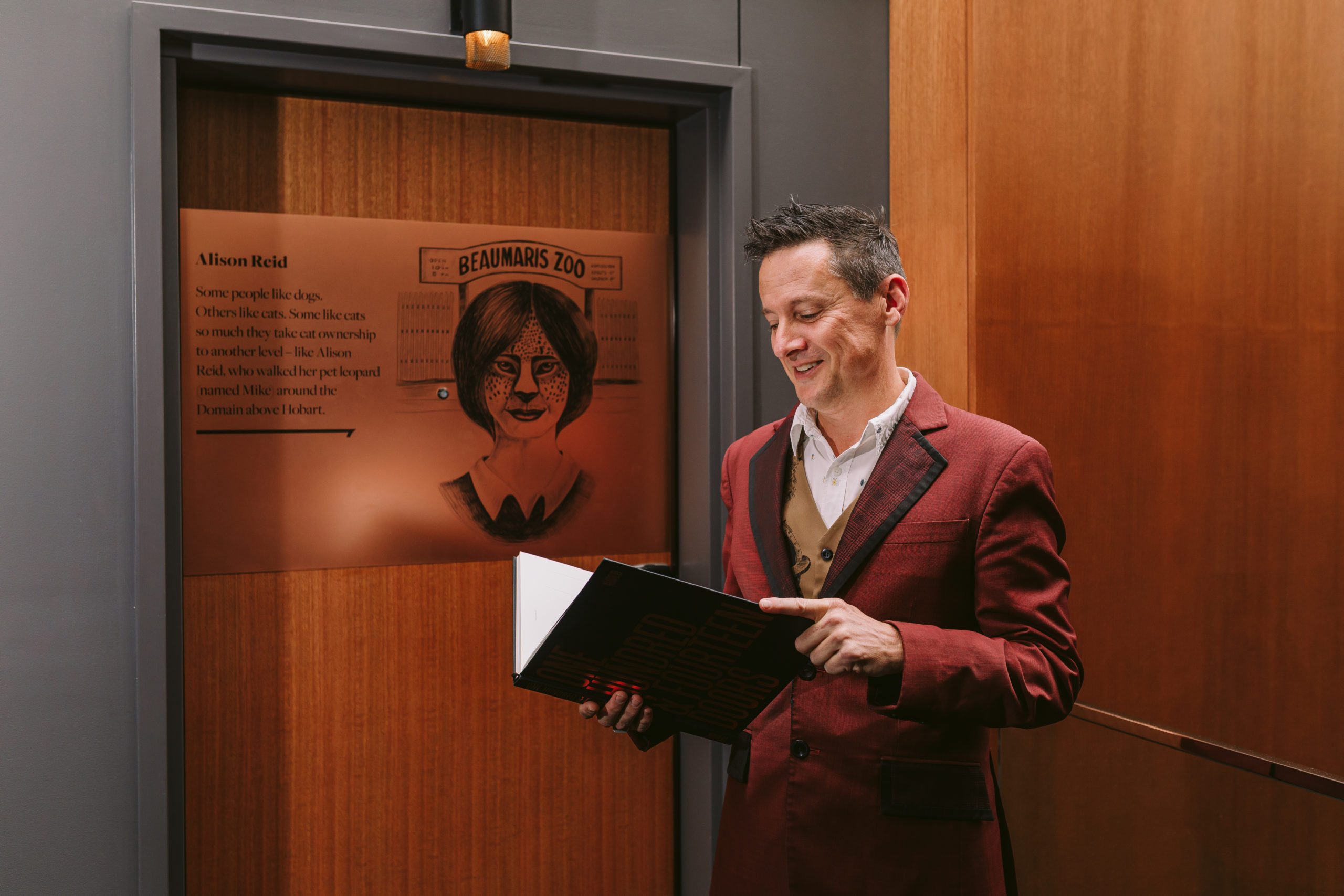

If you’re looking for things to do in Hobart, The Henry Jones Art Hotel offers a range of unique experiences for visitors to the city. Situated in the heart of Hobart’s historic waterfront, let our friendly host guide you through the decades of heritage and artistic talent that have shaped our hotel. From our curated Henry Jones Art Tour to indulgent nearby spa treatments and scenic helicopter flights over the city, we have something to suit every taste and interest.

Whether you’re a foodie looking to book an exclusive dining experience at one of our exceptional restaurants or are simply seeking some adventure, there are various Hobart attractions for you to experience. We have so much to share with you within the hotel and beyond.

Things to Do

We are here to help you make the most of your trip, with some suggestions of things to do in Hobart. We’ve gathered some local highlights to help take the guesswork and research time out of organising Hobart day trips. From helicopter flights that end at vineyards to crispy croissants in historic neighbourhoods, we have something for everyone.

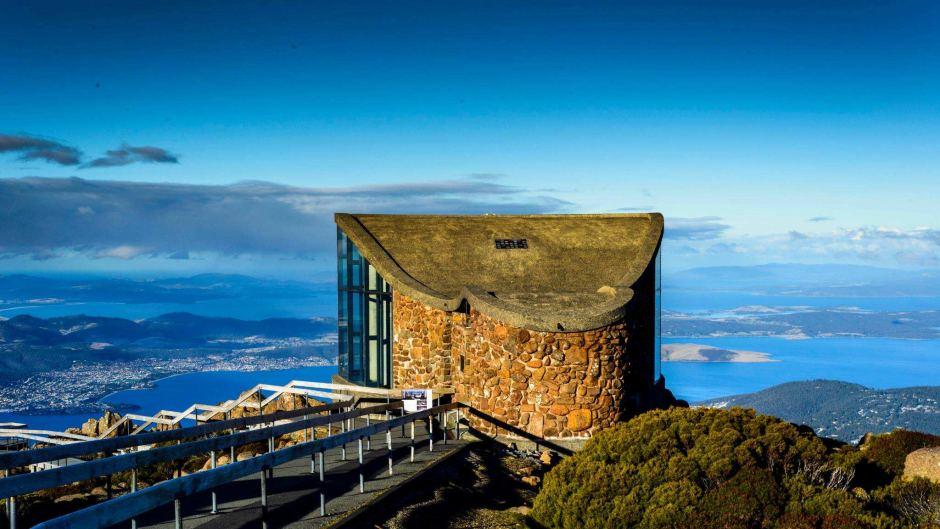

If you are looking for some adventure we can help you get close to wildlife at the Bonorong Wildlife Sanctuary, or perhaps you would enjoy a day trip to the pinnacle of kunanyi / Mount Wellington, 1271 metres up.

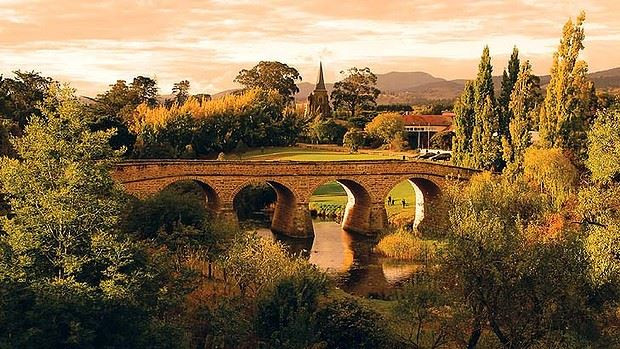

For a more luxurious day trip, we can arrange a visit to a historic town by luxury car, dropping into vineyards en route. The Cascade Brewery, Australia’s oldest operating brewery, is also worth a visit.

Our Concierge team is dedicated to ensuring your stay is your best and can help you with any questions you may have about day tours from Hobart.